Purpose of Equipotential bonding

Equipotential bonding is essentially an electrical connection maintaining various exposed conductive parts and extraneous conductive parts at substantially the same potential.

An earthed equipotential zone is one within which exposed conductive parts and extraneous conductive parts are maintained at substantially the same potential by bonding, such as that, under fault conditions, the difference in potential between simultaneously accessible exposed and extraneous conductive parts will not cause electric shock.

Bonding is the practice of connecting all accessible metalwork – whether associated with the electrical installation (known as exposed metalwork) or not (extraneous metalwork) – to the system earth.

In a building, there are typically a number of services other than electrical supply that employ metallic connections in their design. These include water piping, gas piping, HVAC ducting, and so on. A building may also contain steel structures in its construction. We have seen earlier in this chapter that when an earth fault takes place in an installation, the external conducting surfaces of the installation and the earth mass in the vicinity may attain higher potential with reference to the source earth.

There is thus a possibility that a dangerous potential may develop between the conducting parts of non-electrical systems including building structures and the external conducting parts of electrical installations as well as the surrounding earth.

This may give rise to undesirable current flow through paths that are not normally designed to carry current (such as joints in building structures) and also cause hazardous situations of indirect shock.

There are two aspects to equipotential bonding: the main bonding where services enter the building and supplementary bonding within rooms, particularly kitchens and bathrooms.

Main bonding should interconnect the incoming gas, water and electricity service where these are metallic but can be omitted where the services are run in plastic, as is frequently the case nowadays. Internally, bonding should link any items, which are likely to be at earth potential or which may become live in the event of a fault and which are sufficiently large that they can contact a significant part of the body or can be gripped.

Small parts, other than those likely to be gripped, are ignored because the instinctive reaction to a shock is muscular contraction, which will break the circuit.

Bonding Metal Piping Systems

In each electrical installation, main equipotential bonding conductors (earthing wires) are required to connect to the main earthing terminal for the installation of the following:

- Metal water service pipes

- Metal gas installation pipes

- Other metal service pipes and ducting

- Metal central heating and air-conditioning systems

- Exposed metal structural parts of the building

- Lightning protection systems.

It is important to note that the reference above is always to metal pipes. If the pipes are made of plastic, they need not be main bonded.

If the incoming pipes are made of plastic but the pipes within the electrical installation are made of metal, the main bonding must be carried out, the bonding being applied on the customer side of any meter, main stopcock or insulating insert and of course to the metal pipes of the installation.

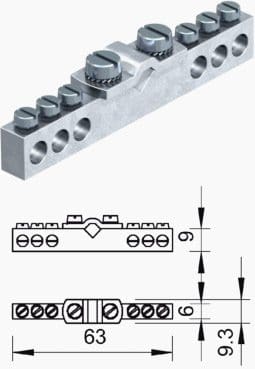

Equipotential bonding terminal for bathroom (OBO)

Many equipment failures in sensitive computing and communication equipment are attributable to the insistence of the vendors to keep them separated from the electrical service earth. Besides equipment failures, such a practice also poses safety hazards particularly when lightning discharges take place in the vicinity.

In such cases, large potential difference can arise for very short periods between metal parts of different services unless they are properly bonded. Some of the case studies in a later chapter deal with this issue.

If the incoming services are made of plastic and the piping within the building is of plastic, then no main bonding is required. If some of the services are of metal and some are plastic, then those that are of metal must be main bonded.

Supplementary or additional equipotential bonding (earthing) is required in locations of increased shock risk. In domestic premises, the locations identified as having this increased shock risk are rooms containing a bath or shower (bathrooms) and in the areas surrounding swimming pools.

There is no specific requirement to carry out supplementary bonding in domestic kitchens, washrooms and lavatories that do not have a bath or shower. That is not to say that supplementary bonding in a kitchen or washroom is wrong, but it is not necessary.

For plastic pipe installation within a bathroom, the plastic pipes do not require supplementary bonding, and metal fittings attached to these plastic pipes also would not require supplementary bonding. However, electrical equipment still does require to be bonded and if an electric shower or radiant heater is fitted, they will require supplementary bonding as well.

Supplementary bonding is carried out to the earth terminal of equipment within the bathroom with exposed conductive part. A supplementary bond is not run back to the main earth. Metal window frames are not to be supplementary bonded unless they are electrically connected to the metallic structure of the building.

All bonding connections must be accessible and labeled:

SAFETY OF ELECTRICAL CONNECTION – DO NOT REMOVE!

Resource: Grounding, bonding, shielding and surge protection – G. Vijayaraghavan

(Buy this book at Amazon)